The Challenge:

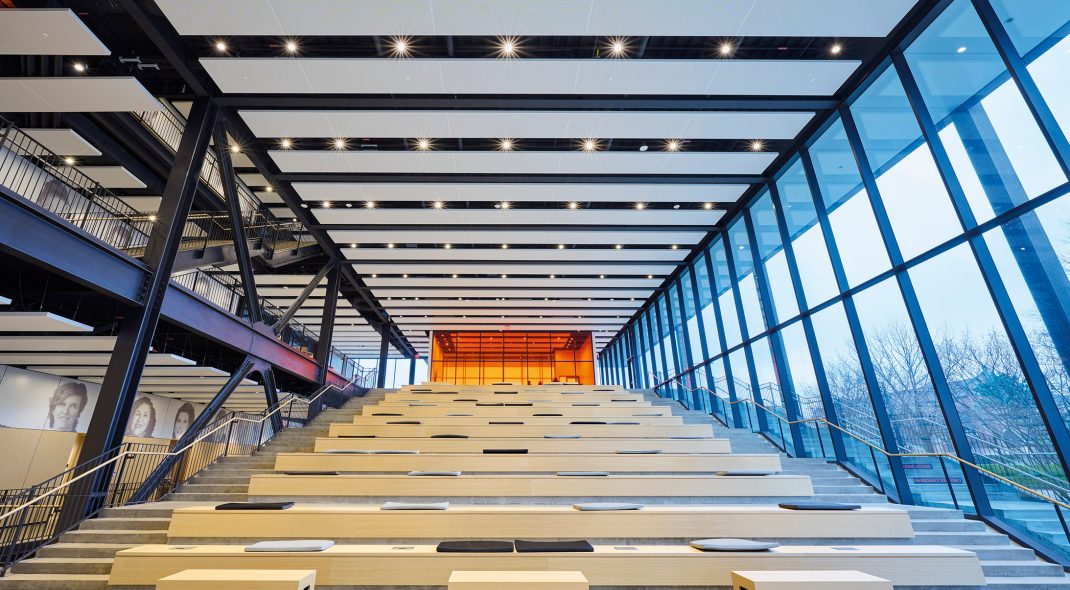

The Campus Instructional Facility at the University of Illinois Urbana-Champaign is a newly constructed five-story building featuring 23 state-of-the-art active learning classrooms, a 500-seat auditorium, “collaboration hubs” on each floor, and a multi-story gathering space called the “Study Steps.” Skidmore Owens & Merril (SOM) architect Kevin O’Connor reports sustainability, especially regarding a reduction in energy consumption, was one of the main challenges in the design of the building.

The Solution:

To achieve the school’s sustainability goals, the new facility features a geothermal energy system, windows with smart glass technology to control incoming light, and METALWORKS Radiant – AIRTITE ceiling panels from Armstrong Ceiling & Wall Solutions, to help heat and cool the building. The aluminum ceiling panels use direct energy transfer from surfaces in a room via modular ceiling panels. Hot or cold water circulates through concealed copper tubing on the back of the panels providing thermal comfort. MEP consultant dbHMS proposed the radiant solution for the facility.

According to the University, the combination of geothermal and radiant systems supplies the building with the equivalent of almost 65 percent of the total building energy demand, helping to conserve energy and reduce costs.

Acoustically, the ceiling panels are perforated and backed with a one-inch-thick encapsulated acoustical infill pad. This results in a Noise Reduction Coefficient (NRC) of 0.75, meaning the panels absorb 75% of the sound that strikes them.

A total of 1,750 radiant ceiling panels in 77 custom sizes totaling over 42,000 square feet were installed. The most common size was 3' x 10' with custom sizes determined by the project geometry and structural elements. Each of the panels has a 3" upturn which serves as trim.

In terms of installation, each panel is independently supported by aircraft cable. Alignment clips were used to square up the panels and keep the rows aligned. Diffusers, lights, and other MEP elements are located between the rows of panels. Factory cut panel penetrations allow for sprinkler integration as required by code. According to manufacturer’s representative Gary Stern of Imbert Inc., installation went smoothly. One reason was the size of the rooms and size of the panels. He says, “It was a case of large panels in large spaces. Compared to 2' x 6' panels, far fewer panels had to be installed.”

O’Connor notes the ceiling provides yet another benefit. “The gaps between the ceiling panels allow engineering students to see the structural elements around and above the panels,” he says. “As a result, the building and the ceiling both serve as teaching tools.” The building itself is now part of the engineering school curriculum.

Environmentally, the building met the school’s sustainability goals as evidenced by its LEED Gold certification. In addition, it is on track to achieve net zero operational carbon and it is anticipated that it will soon be designated LEED platinum.

Project: Campus Instructional Facility

Location: University of Illinois Urbana-Champaign

Architect: Skidmore Owens & Merrill (SOM)

Engineer: dbHMS